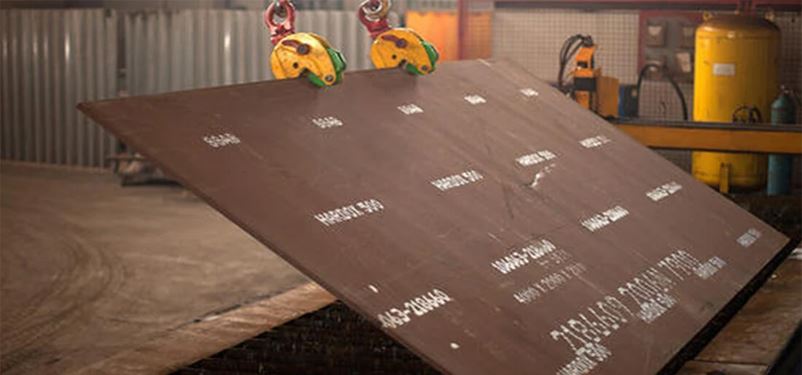

Hybrid Steels is one of the rapidly growing suppliers of quality Hardox Plates recovering the diverse requirements in practically every industry. We are committed to standing up and making the resilient Supplier of Hardox Plates in extremely rough conditions, perfect anti-corrosion properties, and highly reliable performance at elevated temperatures. Our Hardox Plates are designed to handle the most difficult services, including extremely aggressive chemicals and high temperatures, and thus conform to the most stringent application requirements. Being among the foremost Supplier of Hardox Plates in India, we ensure that all our products reflect the highest quality and meet the standards for reliability.

Hardox Plate Supplier provides plates that have high anti-corrosive performance and are best suited for industries relating to marine use, chemical processing, and the generation of power that call for such a great amount of strength against corrosion. We are engaged in supplying high-grade Hardox plates, ensuring that their strength and durability in corrosive environments and at high temperatures remain intact.

Hardox Plates made from Stainless Steel boast excellent thermal stability and, hence are suitable for higher application temperatures, especially in aerospace and related applications to gas turbines. Resistance to thermal cycling ensures that mechanical integrity is maintained for discontinuation-free long-term use.

The mechanical strength of the Hardox Plates is excellent, with great tensile and yield properties. Their robust composition provides great effectiveness in critical applications ranging from deep-sea environments to nuclear facilities.

Their very good performance during normal operating conditions makes them guarantees that even the most complex industrial systems operate safely and efficiently. People also depend on the Hardox Plates for consistent performance, even under extreme conditions.

| Specification | Details |

| Material | Hardox Steel |

| Thickness Range | 4 mm to 130 mm |

| Width Range | 1500 mm to 3350 mm |

| Length Range | 3000 mm to 6000 mm |

| Hardness | 450 HBW to 700 HBW |

| Tensile Strength | ≥ 1400 MPa |

| Impact Toughness | High impact resistance at low temperatures |

| Applications | Mining, Construction, Recycling, Agriculture |

| Standards | ISO 9001, ASTM |

| Grade | Hardness (HBW) | Tensile Strength (MPa) | Yield Strength (MPa) | Applications |

| Hardox 400 | 400 HBW | 1,200 MPa | 900 MPa | General wear and impact applications |

| Hardox 450 | 450 HBW | 1,300 MPa | 950 MPa | Mining, construction, and earth-moving equipment |

| Hardox 500 | 500 HBW | 1,400 MPa | 1,100 MPa | Heavy wear and impact applications |

| Hardox 550 | 550 HBW | 1,500 MPa | 1,200 MPa | Severe wear and high-impact applications |

| Hardox 600 | 600 HBW | 1,600 MPa | 1,300 MPa | Extreme wear and abrasion applications |

| Hardox Extreme | >600 HBW | 1,700 MPa | 1,400 MPa | Heavy-duty wear and high-impact applications |

| Hardox 550 Tuf | 550 HBW | 1,500 MPa | 1,200 MPa | Wear-resistant and high-impact applications |

| Element | Hardox 400 | Hardox 450 | Hardox 500 | Hardox 550 | Hardox 600 | Hardox Extreme | Hardox 550 Tuf |

| Carbon (C) | 0.26 - 0.34% | 0.28 - 0.34% | 0.30 - 0.35% | 0.30 - 0.35% | 0.30 - 0.35% | 0.30 - 0.35% | 0.30 - 0.35% |

| Manganese (Mn) | 1.00 - 1.60% | 1.00 - 1.60% | 1.00 - 1.60% | 1.00 - 1.60% | 1.00 - 1.60% | 1.00 - 1.60% | 1.00 - 1.60% |

| Silicon (Si) | 0.50 - 1.00% | 0.50 - 1.00% | 0.50 - 1.00% | 0.50 - 1.00% | 0.50 - 1.00% | 0.50 - 1.00% | 0.50 - 1.00% |

| Chromium (Cr) | 0.80 - 1.20% | 0.80 - 1.20% | 0.80 - 1.20% | 0.80 - 1.20% | 0.80 - 1.20% | 0.80 - 1.20% | 0.80 - 1.20% |

| Molybdenum (Mo) | — | — | — | — | — | 0.20 - 0.50% | 0.20 - 0.50% |

| Nickel (Ni) | — | — | — | — | — | — | — |

| Phosphorus (P) | ≤ 0.025% | ≤ 0.025% | ≤ 0.025% | ≤ 0.025% | ≤ 0.025% | ≤ 0.025% | ≤ 0.025% |

| Sulfur (S) | ≤ 0.015% | ≤ 0.015% | ≤ 0.015% | ≤ 0.015% | ≤ 0.015% | ≤ 0.015% | ≤ 0.015% |

| Grade | Hardness (HBW) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Toughness (J) |

| Hardox 400 | 400 HBW | 1,200 MPa | 900 MPa | 14% | 27 J at -20°C |

| Hardox 450 | 450 HBW | 1,300 MPa | 950 MPa | 12% | 27 J at -20°C |

| Hardox 500 | 500 HBW | 1,400 MPa | 1,100 MPa | 10% | 27 J at -20°C |

| Hardox 550 | 550 HBW | 1,500 MPa | 1,200 MPa | 8% | 27 J at -20°C |

| Hardox 600 | 600 HBW | 1,600 MPa | 1,300 MPa | 6% | 27 J at -20°C |

| Hardox Extreme | >600 HBW | 1,700 MPa | 1,400 MPa | 5% | 27 J at -20°C |

| Hardox 550 Tuf | 550 HBW | 1,500 MPa | 1,200 MPa | 8% | 27 J at -20°C |

Oil & Gas Industrires

Chemical Industries

Construction Industries

Offshore Pipelines Works

Petrochemical Industry

Shipbuilding Industries

Hydraulic Applications

Piping Systems

Refining Industry

Food Processing Industry

Pulp & Paper Industry

Power Plant Industry

Mumbai, Vijayawada,Vapi,Coimbatore,Patna, Kanpur, Thrissur, New Delhi, Bharuch,Aurangabad,Chennai, Kochi, Thiruvananthapuram, Jamnagar, Rourkela, Visakhapatnam, Vadodara,Indore, Ludhiana, Nashik, Rajkot, Jaipur, Noida, Lucknow, Ranchi,Jodhpur,Bhopal, Gurugram,Hyderabad, Jamshedpur, Ankleshwar,Chandigarh, Nagpur, Faridabad, Bangalore,Ahmedabad, Kolkata, Bhavnagar, Surat

Arabia, UAE,Saudi Arabia, Malaysia, Muscat, China,UK,Congo, Qatar, Bangladesh,Bahrain,Houston,Nigeria, Peru, Venezuela, Poland, Japan, Kuwait, Turkey,UAE,France, United States, Germany, United Kingdom, Iran, Africa, Jordan, Kenya, Sri Lanka, Philippines, Russia, Indonesia,Algeria, Angola, Thailand,Italy, Kazakhstan, Singapore, South Africa, Oman, New Zealand, Canada, Netherlands, USA, Brazil, Vietnam, Dubai, Nepal, Sudan,Australia, Ukraine, Mexico, Denmark.